If you build it, they will come…and be amazed: The 2-day Wikihouse build at World Maker Faire NYC

by MichaelBerliner • November 4, 2013 • collaboration, distributed manufacturing, Maker Movement, shopbot, The Digital Fab Revolution, The New Industrial Revolution

This Fall 2013, a team comprised of software engineers and designers from Colorado and Massachusetts, architects from the UK, and some ShopBotting digital fabbers from Virginia got together and built a house. In two days.

Thousands of Maker Faire-ians walked around inside it and checked it out, and learned about the easy-to-use software employed to design the house — up to 50 or 60 people at a time — and they were suitably amazed at how a structure built with almost NO screws, and no nails at all, would be so simple, elegant and sturdy! And then when the Faire was over, the team took down the house… ready to be put up again.

So what’s a Wikihouse? Based in the UK, the Wikihouse is an open source construction set. Its aim is allow anyone to design, download and ‘print’ CNC-milled plywood houses and components, which can be assembled with minimal formal skill or training. WikiHouse is a non-profit project, developing hardware and software which is open and shared in the commons, owned by everyone.

As Eric Schimelpfenig describes the idea (Eric is a kitchen and bath designer and software engineer who was involved in building the Wikihouse for Maker Faire), “With Wikihouse, if you can use a computer, you can design a house. A real house, set to take in plumbing, electric and insulation. And if you’ve ever put Legos together — or wanted to — now you can build the house you’ve designed, thanks to files made available to anyone, anywhere.”

The NYC Faire project was conceived during the San Mateo Maker Faire this past spring, when software engineers from Sketchup (John Bacus, Mark Harrison and others) got together with Wikihouse architects Alastair Parvin and Nick Ierodiaconou to hatch a plan for the “next big thing,” which turned out to be making the digital model of Wikihouse real in NYC. ShopBot’s Bill Young and digital fabber/builder Robert Bridges contributed their expertise as builders to further inform the design and advise the team about appropriate materials for construction.

Eric expresses a core principle of Wikihouse design as empowering “regular citizens,” (not trained as architects and builders) to design and build what they wish. He explains, “Because the parts of a Wikihouse have engineering already thought into their design, and easy constructability (e.g. no part is too heavy for one person to carry, or unsafe to lift up over your head), the amateur designer/builder can start out having the confidence that he or she can build successfully.”

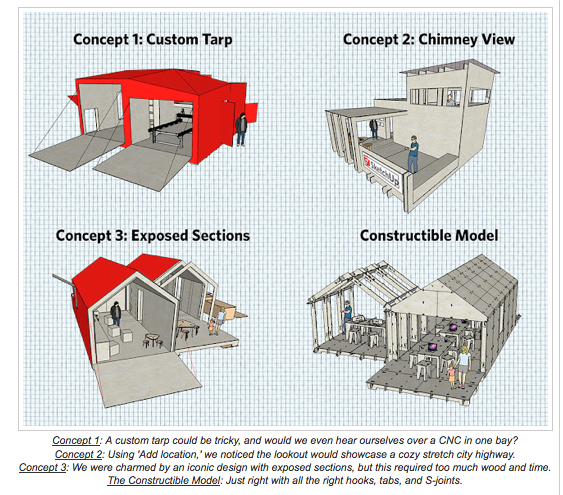

Mark Harrison, the marketing manager at Sketchup who served as project manager on this NYC house build, described the creative process in his Sketchup blog, excepted here:

“Kicking off the project, it was quickly evident that between the SketchUppers and the WikiHouse’rs, there were more than enough architects to go around. Aside from the reality that no one on the team had a CNC router in his garage, we knew we’d need a project partner with tons of CNC experience — and one who wouldn’t laugh off the idea of hammering together a thousand cut pieces in the middle of Maker Faire.”

Mark continues, “Enter our friend Bill Young over at ShopBot Tools. We’d been itching to do a project with Bill since he caught us spreading saw dust all over Maker Faire Bay Area earlier this year. Bill’s practical experience with wood selection, tolerances, and project planning are nicely measured by his ability to engrave anything (onto anything) while generally believing that most things are possible. With the right mix of optimism and practicality, we started trading SKP’s back and forth, hashing out the trade-offs in various design concepts.”

The final model:

Bill Young cut out 1150 parts out of 160 sheets of plywood in preparation for the build…including the mallets that would be used to put together the house.

Looking back on the NYC Maker Faire experience, Mark Harrison commented, “Peoples’ reactions were great; personally I had a wonderful “Aha!” moment when we started to see this house holding 60 people at a time securely! Not only was it easy to construct, it was proven sturdy. Many visitors who know construction were very impressed with the joinery.”

Inside the Wikihouse, Maker Faire attendees of all ages learn about the Wikihouse project and the Sketchup software.

Mark continues, “I think this Wikihouse can become a great “training” project — digital fabbers can use it to design and build storage units and workspaces for their businesses — this would be great for the 100kGarages community to adopt.”

The plans for the Wikihouse are now available online. Click here for the link.

Another important aspect of the Wikihouse is that it’s a “hackable house” — it’s relatively easy to go in and take apart sections of the home to reconfigure/remodel areas of the home to meet the residents’ evolving needs. “As a kitchen and bath designer,” says Eric Schimelpfenig, “this is yet another exciting feature of Wikihouse design. It brings down barriers to making changes to a home — the expense and the complication of a remodel can be lessened considerably.” You can learn more about Eric’s development of easy-to-use kitchen and bath design tools here.

Looking to the future, communities of people who are interested in fostering sustainability could be well served by incorporating “Wiki-building.” You could imagine a group of people buying some land to develop, designing unique and interesting homes — and even sharing their CNC tools and various expertise.. A sort of 21st century “barn raising” applied to home building.

WATCH the time-lapse video of the house going up…. filling up with the visitors…. and then being deconstructed!

Want to learn more about the inspiration for the Wikihouse project? Watch this fascinating TED talk by Wikihouse co-founder Alastair Parvin.