People, Not Pixels: Thoughts on start-up success from the Standing Desk Ninja

by MichaelBerliner • January 22, 2014 • collaboration, community shops, maker spaces, prototyping, shopbot, The Digital Fab Revolution, The New Industrial Revolution • 1 Comment

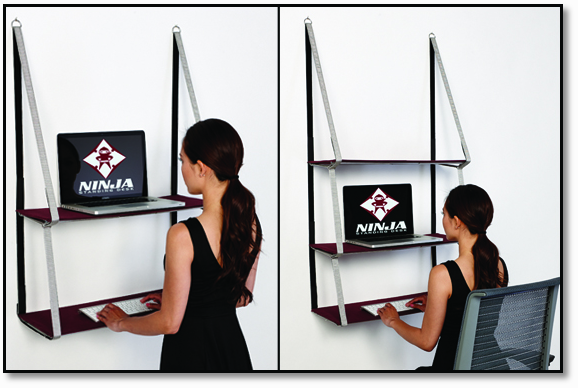

The Ninja Standing Desk is just like it sounds — and it may well be the world’s first portable and affordable version of the permanently installed workstations you see around office and home businesses around the country.

The Ninja Standing Desk is just like it sounds — and it may well be the world’s first portable and affordable version of the permanently installed workstations you see around office and home businesses around the country.

The “Ninja” behind the Ninja Standing Desk (www.NinjaStandingDesk.com) is San Franciscan Dan McDonley, and his product has become a huge hit. It’s designed by Dan here in the U.S., prototyped here, and assembled from parts from here at home. Pretty cool. To help him bring this new product to market, Dan has been making good use of his local San Francisco TechShop, and also reached out to 100kGarages fabbers as part of his vendor-sourcing. It’s an inspiring success story. Here’s the intro video about the Ninja Standing Desk:

It all started because of a bad back.

In the case of the Ninja Standing Desk, turns out necessity was indeed the mother of invention. Dan McDonley had practiced martial arts in earlier years, and suffered some chronic back pain stemming from his practice. Recently the pain was becoming exacerbated by hours spent in an activity that is all too common for most of us — sitting hunched over a computer keyboard. (I just paused as I wrote this and sat up straight!)

McDonley had the opportunity to use a standing desk and appreciated the benefits — less back pain, more energy throughout the day, more productivity. Seeing how expensive the permanent versions were, he was inspired to design, build and sell his own portable and affordable one. Road warrior/business Ninjas can fold it up and carry it easily in its nifty bag, and it either mounts over a door or cubicle wall, or more “semi-permanently” with easy to remove specialty drywall hooks.

A highly successful Kickstarter campaign empowered Dan with the funds to get started. And he says that being able to prototype and manufacture parts for the Desk at his local TechShop “opened up a world of possibilities for me.”

A highly successful Kickstarter campaign empowered Dan with the funds to get started. And he says that being able to prototype and manufacture parts for the Desk at his local TechShop “opened up a world of possibilities for me.”

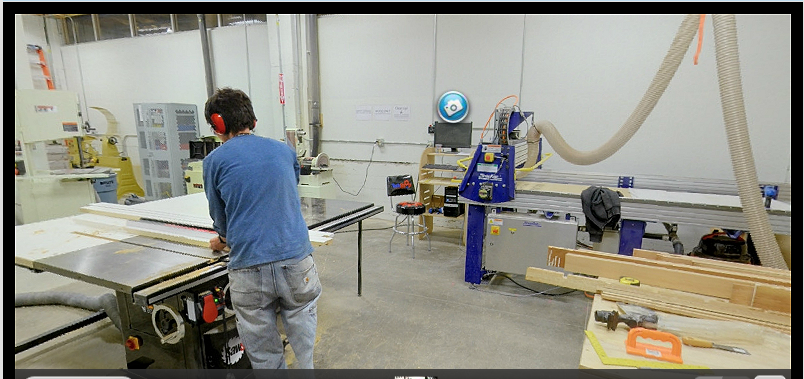

Off to his factory: the TechShop San Francisco.

At TechShop SF, Dan began by cutting his design for the two 11″ x 26″ shelves — each of which folds to 11″ x 13″ — using their ShopBot 4 X 8 gantry tool. The shelving material is 1/8″ inch tempered hardboard which is then surrounded by cloth covers. Dan created a custom toolpath that allowed him to use the ShopBot to cut between 40 and 50 sheets of material in about 4 hours, about 5 minutes per sheet. He’s also been using more traditional tools such as a panel saw and chop saw in his cutting process.

As I spoke with Dan about his vendor-sourcing process, he surprised himself when he realized that he manages over a dozen different contractors in order for him to assemble each Ninja Standing Desk — including suppliers of drywall mounts, metal ring hardware, strapping, shelving fabric, aluminum support poles, the travel cases, his sheet metal supplier, booklet printer, his fabric cutting and sewing team, and more. All of the vendors for the Ninja Standing Desk are located in the United States; the sheet metal vendor and providers of cutting and sewing services are in the Bay Area.

Dan recounted that he also reached out via 100kGarages.com in search of a fabber with an appropriately sized and equipped CNC router to take over the cutting that he’d been doing at TechShop, but wasn’t able to succeed there. “I found few in the area with vacuum hold-downs, and unfortunately couldn’t find someone open to collaborating on the production process such that they could work as cost-efficiently as I can by myself.” When I asked Dan to sum up lessons learned from identifying and working with vendors, he said, “For me anyway, the successful way is to ‘show up.'” To make it work, Dan will pay visits to his vendors or the other way around. “Personal contact is everything,” Dan says. “It’s the key to building working relationships.”

It seems to me that there’s a simple truth here, that even in our world of internet-connectedness, it’s too easy for dialogue to remain impersonal, to dismiss an opportunity if it doesn’t sound perfect in the first instant, all too easy to fall into the trap of not using methods of communication that can help people succeed better in collaborating. You know… the phone. A video call. Or an in-person visit. “People, not pixels” is an important key to success.

My take-away: if you’re using 100kGarages, after the initial connection be mindful of taking it quickly to the next level. Jump on a phone call so you can really discuss things — hear each other’s voice. Use technology like video calls either by Google hangout, Facetime or whatever technology is handy for you to work face to face even when you’re separated by miles.

And let’s talk about China.

The early success of the Ninja Standing Desk has caught the attention of quite a bit of press. There’s an interesting piece in Forbes which goes into a bit of depth about the pros and cons that Dan considered regarding manufacturing the product here in the U.S. vs in China. Some of the issues it touches on are: the difficulty to maintain quality control from afar, and the fact that the product contains no electronics made the choice of keeping manufacturing here easier to make.

Dan shared some thoughts with me about this. “I think that one of the (many) crippling blows that outsourcing to China has dealt to the U.S.’s potential for bringing manufacturing home, is that they are so well organized,” say Dan. “For a large run of product, in China all the vendors are gathered together, often under the same roof. Here in the U.S., vendors are scattered. It can be daunting to figure out how to manage a process here.”

“On the other hand, where China is much less appropriate is in doing smaller manufacturing runs,” Dan noted. “If we can figure out how to gather vendors better here, like through networks such as 100kGarages, it can mean the world to a local manufacturer with a good idea for the market.”

What are your thoughts, Garagers?

…..

BTW, you can check out ShopBot’s CNC tools here. Get in touch with ShopBot by phone at 888-680-4466, or use this online contact form.

Pingback: Try blogging! It’s good — and good FOR you! | Brand Improv