A Maker’s Journey to Maker PRO: The Timbrr Stylus story

by MichaelBerliner • May 15, 2014 • community shops, Design, Maker Movement, maker spaces, prototyping, shopbot, The Digital Fab Revolution, The New Industrial Revolution

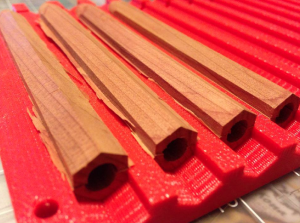

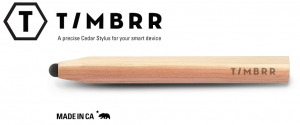

The first thing that strikes you when you step inside Dom Peralta’s garage/maker space in San Mateo isn’t necessarily the high-pitched drilling of his ShopBot Desktop’s spindle. Rather it’s the very pleasant and heady aroma of natural California cedar. That’s because the ShopBot is hard at work precision-cutting wooden dowels of cedar for the Timbrr Stylus, an ergonomic stylus for you to use with your touchscreen tablet or smartphone.

The Timbrr Stylus is the brainchild of the team of Dom Peralta and Jon Corpuz, corporate industrial designers by day, and entrepreneurial Maker Pros on nights, weekends….and just about every possible waking moment. Right now they’re hard at work getting Timbrr Styluses completed to show off at the 2014 Maker Faire in San Mateo, and putting the final touches on a Kickstarter campaign to help the duo expand production. UPDATE! The Kickstarter for the Timbrr is now live. Please check it out and show your support.

Before we dive into the Timbrr Stylus development, meet the Makers. Here’s Dominic Peralta:

Before we dive into the Timbrr Stylus development, meet the Makers. Here’s Dominic Peralta:

Dominic Peralta attended San Jose State University for Industrial Design, and studied fine art in Florence, Italy, before becoming a designer. He started his career at Smart Design USA and then New Deal Design, and then started working full time for one of his clients, Kensington. He then joined Speck Design where he continues to drive design for a variety of products. All the while he has been teaching at SJSU.

…..and Jon Corpuz:

Jon Corpuz is also a proud alumnus of SJSU’s Industrial Design program (both he and Dom have gone on to teach there). After graduating, Jon worked at exodesign on a variety of products from medical to consumer goods. Then he joined Kensington, first designing PC accessories and then iPad and iPhone cases, docks, etc. That experience helped Jon land his next and current position at Nook Media, where he is leading the design front for accessories for eReaders and Nook tablets (cases, batteries, audio, and chargers).

Jon noted, “I am so happy to say that Dom and I have also started our own design consultancy, Peralta/Corpuz Designs. We want to open up our expertise and knowledge to the world to help others design thoughtful solutions for users.”

Here’s how Dom describes the Timbrr Stylus on its Facebook page: “Cedar meets technology in this gorgeous machined, hand-finished stylus for your tablet. Each Timbrr is unique to the grain of the tree it was born from. This stylus brings the warmth and natural feel of wood with the aroma of cedar to your finger tips as it is fueled by its copper core and capped with a capacitive rubber tip. It helps you interact with your tablet as you type, tap and draw anything from your imagination… The California incense cedar will age with a fine patina too! ”

How can you successfully swipe a touchscreen with a piece of wood, you may ask? (unless you are well-versed in science and/or technology, then you probably don’t have to ask).

Dom explained that touch screens are driven by capacitive technology: the static electricity emitted from your body is transmitted by your finger when you touch, swipe and click. For this reason, material choice is crucial to making a capacitive stylus work. The natural resins in cedar wood are a good transmitter of static electricity; when you hold the stylus, your energy is conducted through the wood to the stylus’ copper core and down to its rubber tip.

How they got that idea, and, how Maker Pros are born!

Dominic tells the story…”Jon Corpuz and I were sitting one day play the Draw Something app by OMG Pop (Zynga), and it dawned on us….we need to make a stylus for this game! We ran to the woodworking store, bought some pine dowels and made a very quick prototype to prove the concept. It worked! We continued making prototypes to test out shapes and sizes until we found the one that felt best.”

“At that point we were kind of at a junction in the road…. do we find a woodshop or machine shop to rent time (e.g.TechShop, etc), do we hire someone to help us make the parts…or do we do it all on our own? With some research and a perfectly timed email from Shopbot — in 2013, ShopBot held a promotion with Autodesk to help teachers and schools purchase ShopBot Desktops — i got this idea in my head that we could just buy a ShopBot and make it all on our own in our garage.”

“So the decision was made,” Dom continued. “Let’s get a ShopBot, put it in my garage and make this the beginning of our Maker Space. So we called up Shopbot, placed the order and in a few weeks we had it all set up and running. We got our training work done on the ShopBot (set up and follow along tutorials) , and we were off and running.”

“Since we now had a controllable CNC at our disposal, we started testing out manufacturing steps and processes for making Timbrr real. We probably made about 500 different iterations before settling on the final assembly, look and feel. Having our own ShopBot was really the only way for us to afford to get so much time on the machine that allowed us get to the precise details we were looking for. There we some hiccups along the way…machine not cutting properly, software issues on my computer and at one point the thing just was not working. But all the support team at ShopBot was so great that we quickly got it back up and running and on our way to finalizing our Timbrr Stylus. Today, he have it cutting parts smooth, accurate and with a lot of ease! ”

As a side note, Dom mentioned that although he had “a ton” of experience with CAD due to his education and work as an industrial designer, he knew precious little about CAM and using CNC tools. To help him with the initial learning curve on the ShopBot, Dom noted that “he has turned to the ‘robust educational network’ that ShopBot provides — the forum, the videos and online training classes.”

What do you do with buckets of leftover cedar shavings, anyway?

The answer turns out to be all in the family…the Peralta family. Dom explained, “In the process of working with the ShopBot tool we discovered other productive uses for the cedar material — increasing the possiblities for product development and reducing waste. The ShopBot does such clean cuts and my dust collection system was quite efficient. I had an instinct to keep all of the shavings from the cedar wood, not just because of the pleasant aroma but because I just knew there could be some other uses for this.

Dom continues, “One day my Mom said, ‘I bet you could make soap using the shavings.'” Well now they have gone on to develop a natural soap of palm oil, shea butter and essential oils, and each bar contain about 15% shavings of the cedar. It has the consistency of Lava® soap, with the cedar ground into a fine, abrasive powder. And Dom’s brother, yet another designer/maker, has been using the cedar leftovers to make incense and firestarters.

Dom summed it up: “Fabrication technology really makes anything possible!”

Finally, The Maker Movement appears to have deep roots.

Many people we’ve interviewed about the Maker “movement” have noted the debt that they owe to their forebears. As it turns out, Dom comes from a long tradition of makers. Dom relayed this story. “I’ve always been a maker. I started with some 4th grade invention projects that my dad helped me out with. He always encouraged me to make things and break things 🙂 My two grandpa’s were also tinkerers and they taught me so many fantastic qualities about just making something work with the items that you have lying around. My nono August Pini was especially influential on me when it comes to making things. He had a great work shop and always let me play with tools that I probably shouldn’t have been using at a young age (saws, drills, sanders, grinders, etc!). He worked as a garbage man his whole life and he certainly took the phrase ‘one person’s trash, other peoples treasures’ as a life motto. He could take an old chair and remake it like no one else I have seen! Still today I use many of the tools that he passed down, as well as tool from other relatives and stuff I have found from our local community (Craigslist and garage sales). I spend a lot of time out in our little Maker Space (my garage), using all these tools that help to make ideas real. For me the perfect moment is when I’m in my Maker Space, listening to a baseball game and using the tools around me to make an idea real….oh and it’s nice to toss a beer in there now and again too 🙂 ”

Jon Corpuz reflected on his family roots and how they have inspired him to Make. “My father always wanted me to become a mechanical engineer as he was a machinist working in the Silicon Valley. So, naturally he bought me tons of Legos, Capsela, and Contstrux toys, helping to fuel my creativity and exploration of technology. Growing up I also drew a lot and dreamed of working at Disney. When I stumbled upon Industrial Design in college, I realized I had found a perfect major that combined both my sketching/drawing skills and desire to build/fabricate/make things. I come from a background of makers, where my dad and uncles made their own toys in the Philippines as kids. My grandfather was a highly skilled carpenter who was trained by a Japanese craftsman. I wish he could see what I am working on today, because he would be so proud that I am a reflection of him and his love for the craft of making. So, making runs deep in my blood, grafted onto my DNA and I try to inspire my nieces and nephews to be makers too. Making to me is taking ideas, thoughts, and solutions and making them tangible things people can hold and experience. It’s taking things apart, dissecting and analyzing them to discover how its put together, how its made, and how it works. I continue to be fueled by my curiosity, passion for design, and desire to make things better for the world.”

If you’re in San Mateo for Maker Faire 2014, be sure to stop by ShopBot’s booth, and the Timbrr booth where the ShopBot Desktop will be doing live cutting of the cedar. “Timbrrrrrr!”