Press Fit: A Kickstarter Success via MIT’s FabLab and 100kGarages

by MichaelBerliner • September 18, 2014 • Design, distributed manufacturing, Featured 100k Users, furniture, Maker Pro, The Digital Fab Revolution, The New Industrial Revolution • 0 Comments

Press Fit makes an affordable, portable standing desk of quality maple that packs flat and assembles in seconds without screws or tools. Sustainable and locally made!

David Yamnitsky graduated in June of 2014 with a BS in Electrical Engineering and Computer Science from MIT, and is continuing as a graduate student at the Center for Bits and Atoms at the MIT Media Lab. He never thought when he entered MIT, that a couple of years later he’d be launching a forward-thinking furniture business, but this is the kind of life-changing adventure that can start when a student takes the “How to Make Almost Anything” course at MIT’s FabLab.

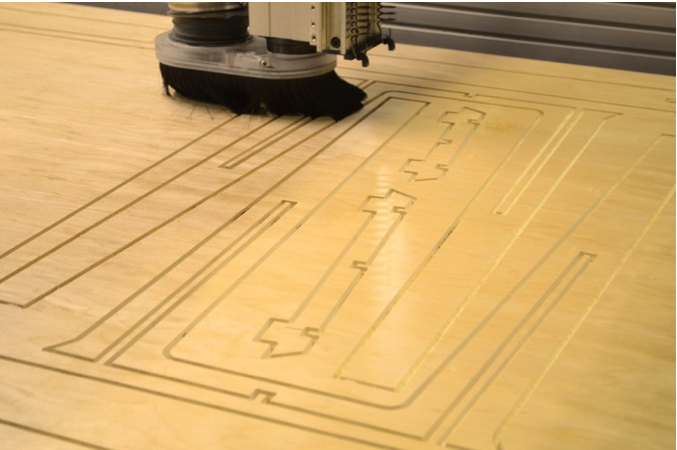

I spoke on the phone with David recently; he described the origins of the project. “Each week students make something using a different digital fabrication tool. For the week on CNC routing — the assignment being ‘Make Something Big’ — my friend Isabella suggested making a standing desk. She fell in love with standing at work while interning in the Bay Area but couldn’t afford to buy a standing desk for over $1000.”

“As engineers, we took to the drawing board. We knew we could design a desk for less money, but we wanted to do more than just make it cheaper. We wanted it to be made of sustainable materials, locally manufactured, and since we were always moving from place to place, we wanted it to be easy to assemble and dis-assemble.”

The result is the Press Fit Standing Desk, the most affordable standing desk on the market that assembles in seconds without screws or tools (the Press Fit’s starting price is $279, available from their website store). Supporting sustainability is a priority for David and Isabella, so they make the Standing Desk with a quality pre-finished maple that is 100% formaldehyde-free, healthier for people and the planet. Its design allows for easy assembly with no tools or screws.

David and Isabella launched the Press Fit Standing Desk on Kickstarter and were overwhelmed with the response. As of the time of this article, they are starting to fulfill the Kickstarter orders and are taking pre-orders from anyone who missed the campaign. Meet them here, on their Kickstarter video…

David and Isabella launched the Press Fit Standing Desk on Kickstarter and were overwhelmed with the response. As of the time of this article, they are starting to fulfill the Kickstarter orders and are taking pre-orders from anyone who missed the campaign. Meet them here, on their Kickstarter video…

David and Isabella used the ShopBot CNC router at MIT to make their first Press Fit standing desks. To move into production locally, they jumped onto 100kGarages.com, a free-to-join community where digitally-based designers can connect with people running digital fabrication businesses. Their 100kGarages search led them to AListWoodworks in Whitinsville, MA, which is convenient to David’s home. He can easily oversee quality control and address any issues in person.

I spoke with David about the possibilities for distributed manufacturing of the Press Fit desk. He’s already begun conversations with other 100kGarages fabbers on the West Coast to be able to serve customers there, using materials local to California and keeping shipping costs low. “Distributed manufacturing brings its own challenges,” David said. “The most important being quality control of material; we need to make sure that there is a consistency to the sourcing of the wood. We’re thinking of involving the customer in the decision-making process regarding material. We could identify a locally-sourced material that we are comfortable with, and that could be the lowest cost desk. We could also offer other choices of more exotic woods, but the customer would have to pay more for us to get that wood for the manufacture.”

I like the philosophy of involving the customer in making choices that affect sustainability. I think it opens our eyes as consumers to being more conscious of how we spend our money on the products we need. For those who have access to CNC technology, either their own tool or one at a TechShop or other maker space, Press Fit has plans to make the digital files available on a non-commercial license basis for a low cost. So, you’ll be able to make your own Press Fit Standing Desk!